汽车已经成为人们出行的必不可少的交通工具,为汽车电子设备选择高可靠性的电容器已然是工程师的工作日常。首先必须清晰的了解每种不同规格电容器的技术参数和性能特征,其次要根据汽车电子的环境和特殊应用场景,才能选择最具性价比和最可靠的尊龙凯时的解决方案。

automobile has become an indispensable means of transportation for people to travel, and it is the daily work of engineers to select high reliability capacitors for automotive electronic equipment. first of all, we must clearly understand the technical parameters and performance characteristics of each capacitor with different specifications. secondly, we must select the most cost-effective and reliable solution according to the environment and special application scenarios of automotive electronics.

电容在汽车电子方面的应用通常可以总结归纳为以下六个应用领域:

the application of capacitors in automotive electronics can generally be summarized into the following six application areas:

1.动力系统控制:电动机、变速器和排放控制。如今电动汽车的蓬勃发展为电源转换和控制电子设备增加了许多新的机会。

power system control: motor, transmission and emission control. nowadays, the vigorous development of electric vehicles has increased many new opportunities for power conversion and control electronic equipment.

2.车辆控制:防抱死制动、主动悬架、牵引力控制、动力和四轮驱动转向。

vehicle control: anti lock braking, active suspension, traction control, power and four-wheel drive steering.

3.安全性、舒适性和便利性:安全气囊执行器、防撞、温湿度控制、巡航控制和防盗。

safety, comfort and convenience: airbag actuator, anti-collision, temperature and humidity control, cruise control and anti-theft.

4.车内娱乐系统

in car entertainment system

5.驾驶员信息显示和声音警告系统

driver information display and audible warning system

6.诊断和维修

diagnosis and maintenance

那么如何根据汽车的主要工作环境和应用领域来选择适合的电容器呢?通常,大多数电容器属于两种基本结构类别之一:静电(聚合物薄膜和陶瓷电容)和电解(钽和铝)电容器。静电电容器是非极化器件,通常表现出非常低的等效串联电阻(esr)和阻抗。电解电容器通常具有更高的电容值,但会被极化。

so how to choose the appropriate capacitor according to the main working environment and application fields of the car? in general, most capacitors fall into one of two basic structural categories: electrostatic (polymer film and ceramic capacitors) and electrolytic (tantalum and aluminum) capacitors. electrostatic capacitors are nonpolarized devices, which usually exhibit very low equivalent series resistance (esr) and impedance. electrolytic capacitors usually have higher capacitance values but are polarized.

钽电解电容

tantalum electrolytic capacitor

钽电解电容一般是额定电压从2.5vdc至63vdc的贴片器件,采用125v轴向引线。注意:为了获得最高的可靠性,固体钽电容的实际施加电压降额至额定电压的50%,钽聚合物和湿块状轴向钽电容则降额至80%。

tantalum electrolytic capacitor is generally a chip device with rated voltage from 2.5vdc to 63vdc, and 125v axial lead is used. note: in order to obtain the highest reliability, the actual applied voltage of solid tantalum capacitors is derated to 50% of the rated voltage, and tantalum polymer and wet bulk axial tantalum capacitors are derated to 80%.

钽电解电容随着时间和温度的变化具有非常稳定的电气特性

tantalum electrolytic capacitors have very stable electrical characteristics as time and temperature change

贴片钽电容的容量最高为2,200μf,轴向湿块钽电容的最大容量可达10,000μf。

the maximum capacity of chip tantalum capacitor is 2200 μ f. the maximum capacity of axial wet block tantalum capacitor can reach 10000 μ f。

浪涌测试/筛选和更大的贴片外壳尺寸(低esr值和大电容值)。

surge test/screening and larger chip enclosure size (low esr value and large capacitance value).

在正常电压降额使用条件下的典型失效率为5fit至15fit(每10亿小时失效数)。

typical failure rates under normal voltage derating service conditions are 5fit to 15fit (failures per billion hours).

铝电解电容

aluminum electrolytic capacitor

贴片式铝电解电容的额定电压从6.3vdc至450vdc,大罐式铝电容则有更高的电压。

the rated voltage of the chip type aluminum electrolytic capacitor is from 6.3vdc to 450vdc, and the large tank type aluminum capacitor has a higher voltage.

温度等级有85℃、105℃或120℃。

the temperature grade is 85 ℃, 105 ℃ or 120 ℃.

贴片式铝电容的最大容量为10mf。

the maximum capacity of chip type aluminum capacitor is 10mf.

无需浪涌电流筛选。

no surge current screening is required.

铝电解电容具有自然磨损机制,在完全额定电压和最高温度条件下的使用寿命将限制为5,000小时。如果降额至额定电压的80%,使用寿命可延长两倍。

the aluminum electrolytic capacitor has a natural wear mechanism, and its service life under fully rated voltage and maximum temperature conditions will be limited to 5000 hours. if the rating is reduced to 80% of the rated voltage, the service life can be extended twice.

陶瓷电容

ceramic capacitor

陶瓷电容的额定电压从6.3vdc到5,000vdc(大多数使用场合为100v或更低);电压无需降额使用,但必须考虑电容的电压系数。在额定电压或接近额定电压下工作时,多层陶瓷电容(mlcc)的有效电容值可能最多会损失40%。

the rated voltage of ceramic capacitor ranges from 6.3vdc to 5000vdc (100v or less for most applications); the voltage does not need to be derated, but the voltage coefficient of the capacitor must be considered. when working at or near the rated voltage, the effective capacitance value of multilayer ceramic capacitor (mlcc) may lose up to 40%.

陶瓷电容的工作温度可以超过150℃。

the working temperature of ceramic capacitor can exceed 150 ℃.

无极化(在高速插入时可大电流充电)。

no polarization (it can be charged with large current during high-speed insertion).

陶瓷电容具有非常低的esr和直流漏电流。

ceramic capacitors have very low esr and dc leakage current.

典型失效率小于1fit;典型失效模式是短路或参数漂移。

typical failure rate is less than 1fit; the typical failure mode is short circuit or parameter drift.

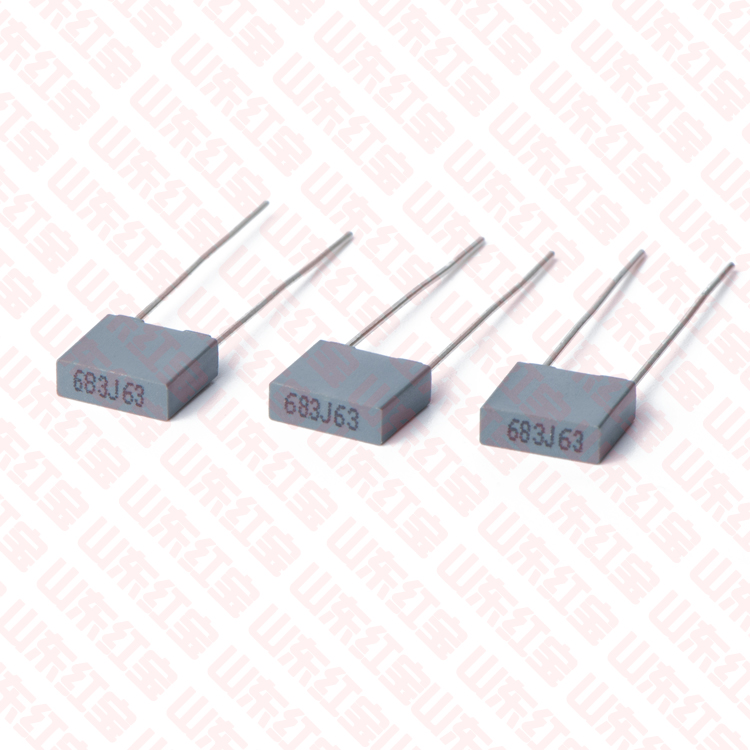

聚合物薄膜电容

polymer film capacitor

额定电压从16vdc至2,000vdc;无需降额工作。

rated voltage from 16vdc to 2000vdc; no derating is required.

大多数聚合物薄膜电容的最高工作温度为105℃(pps电容为125℃)。

the maximum operating temperature of most polymer film capacitors is 105 ℃ (pps capacitors are 125 ℃).

超低的esr和直流漏电流

ultra low esr and dc leakage current

典型失效率小于5fit;典型失效模式是开路或参数漂移。

typical failure rate is less than 5fit; typical failure modes are open circuit or parameter drift.

汽车应用中表贴型号产品比较有限。

the surface mounted products are limited in automotive applications.

确定哪种电容器类型最适合给定应用并不总是那么容易。除了以上的各种参数、性能等因素,还要综合考虑成本、尺寸和可制造性同样很重要。

it is not always easy to determine which capacitor type is best suited for a given application. in addition to the above parameters, performance and other factors, it is also important to comprehensively consider the cost, size and manufacturability.